The construction industry is continually evolving, with a strong emphasis on sustainable practices and innovative solutions. Geotextile fabric plays a pivotal role in this evolution, particularly in mitigating soil erosion and enhancing the stability of infrastructure projects. In this article, we’ll delve into the intricacies of geotextile fabric mitre and geotextile non woven fabric, exploring their applications, benefits, and significance in Indonesia’s construction landscape.

Understanding Geotextile Fabric Mitre

Definition and Purpose

Geotextile fabric mitre refers to a specialized material designed to reinforce soil and prevent erosion. Acting as a barrier, it enhances soil stability and offers long-term support to various construction projects.

Applications in Construction

The versatility of geotextile fabric mitre is evident in its wide range of applications. From road construction to slope stabilization, this fabric provides a durable and cost-effective solution to address various engineering challenges.

Advantages in Mitigating Soil Erosion

One of the primary advantages of geotextile fabric mitre is its ability to reduce soil erosion. By creating a barrier that prevents soil movement, it safeguards infrastructure and promotes sustainable development.

Exploring Geotextile Non woven Fabric

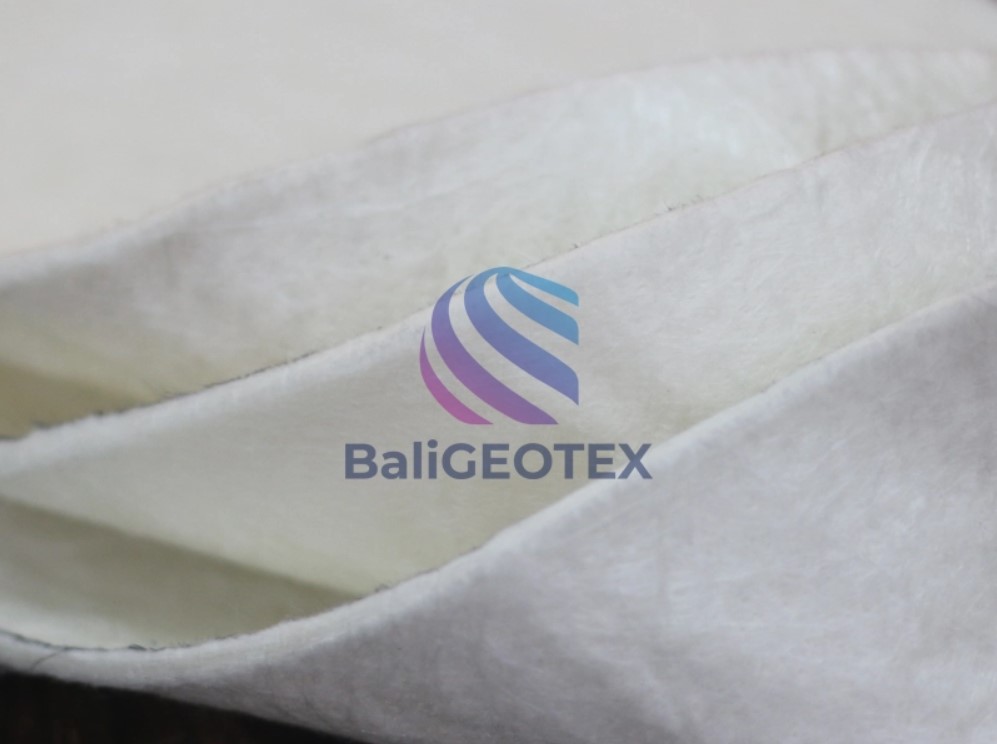

Characteristics and Composition

Geotextile non woven fabric differs in composition from traditional woven fabrics. It is made from a combination of synthetic materials, offering increased strength and resistance to environmental factors.

Environmental Benefits

An essential aspect of geotextile non woven fabric is its eco-friendly nature. This fabric promotes environmental sustainability by preventing soil degradation and supporting vegetation growth.

Versatility in Infrastructure Projects

From drainage systems to soil stabilization, geotextile non woven fabric is highly versatile. Its adaptability makes it a preferred choice for engineers and construction professionals involved in various projects.

The Role of Geotextile in Indonesia

Growing Demand for Geotextile Solutions

Indonesia’s growing infrastructure demands have led to an increased need for geotextile solutions. The fabric’s role in addressing specific challenges has positioned it as a crucial component in construction projects.

Impact on Sustainable Development

Geotextile’s contribution to sustainable development in Indonesia is notable. As the nation prioritizes environmentally friendly practices, the use of geotextile aligns with these goals.

Specific Applications in the Indonesian Context

The unique environmental conditions in Indonesia necessitate specific applications of geotextile fabric. Its use in coastal protection, road construction, and agricultural projects underscores its adaptability.

Geotextile Non woven Factory in Indonesia

Overview of the Manufacturing Process

Understanding the manufacturing process is crucial for assessing the quality of geotextile fabric. Indonesian factories adhere to international standards, ensuring the production of high-quality materials.

Quality Standards and Certifications

When choosing geotextile, it’s essential to look for certifications that guarantee compliance with industry standards. These certifications ensure the fabric’s effectiveness and longevity in various applications.

Role in Supporting Local Infrastructure Development

Geotextile non woven factories in Indonesia play a pivotal role in supporting local infrastructure development. By providing materials that meet international standards, these factories contribute to the nation’s growth.

Choosing the Right Geotextile Fabric

Factors Influencing Selection

Selecting the right geotextile fabric involves considering factors such as soil type, project scale, and environmental conditions. An informed decision ensures optimal performance and long-lasting stability.

Case Studies Demonstrating Successful Applications

Real-world examples showcase the effectiveness of geotextile fabric in diverse projects. Case studies provide insights into how the fabric addresses specific challenges and ensures project success.

Recommendations for Different Projects

Tailoring geotextile fabric choices to specific projects is essential. Recommendations based on project requirements, budget constraints, and environmental considerations guide engineers in making informed decisions.

Advantages of Geotextile in Construction

Enhanced Soil Stability

Geotextile fabric enhances soil stability by preventing soil movement and erosion. This, in turn, improves the durability and longevity of infrastructure projects.

Cost-Effectiveness and Durability

The cost-effectiveness of geotextile fabric, coupled with its durability, makes it a preferred choice for construction projects. It offers long-term benefits, minimizing the need for frequent maintenance.

Environmental Sustainability

Incorporating geotextile in construction aligns with environmental sustainability goals. The fabric promotes responsible construction practices by minimizing the environmental impact of projects. Its ability to support vegetation growth and prevent soil degradation contributes to a more sustainable and eco-friendly construction industry.

Challenges and Solutions

Common Challenges in Geotextile Implementation

While geotextile fabric offers numerous benefits, it’s essential to address common challenges. Issues like installation difficulties and incorrect material selection can be mitigated with proper planning and expert guidance.

Innovative Solutions and Best Practices

Innovation in geotextile technology has led to solutions for overcoming challenges. Best practices in installation, maintenance, and project planning ensure the optimal performance of geotextile fabric in diverse applications.

Overcoming Misconceptions About Geotextiles

Misconceptions about geotextiles may hinder their widespread adoption. Educating stakeholders about the fabric’s benefits, cost-effectiveness, and long-term value is crucial in dispelling myths and encouraging informed decision-making.

Geotextile Fabric Mitre vs. Non woven Fabric

Key Differences

Understanding the distinctions between geotextile fabric mitre and non woven fabric is crucial for choosing the right material for a specific project. Differences in composition, strength, and application suitability guide engineers in making informed decisions.

Choosing the Right Type for Specific Projects

Selecting the appropriate geotextile type depends on project requirements. Whether it’s a road construction project, slope stabilization, or coastal protection, tailoring the material choice ensures optimal performance and longevity.

Complementary Applications

In some cases, a combination of geotextile fabric mitre and non woven fabric may be ideal. Their complementary properties can address various aspects of a construction project, offering a comprehensive solution for enhanced stability.

Future Trends in Geotextile Technology

Emerging Technologies in Geotextile Manufacturing

The continuous evolution of geotextile technology introduces cutting-edge manufacturing methods. Innovations such as smart geotextiles with monitoring capabilities and improved materials enhance the fabric’s effectiveness.

Anticipated Advancements in the Industry

As the construction industry embraces sustainability and technological advancements, geotextile fabric is likely to witness further improvements. Anticipated advancements include increased durability, eco-friendly materials, and enhanced application versatility.

Implications for Construction and Environmental Conservation

The future of geotextile technology holds promising implications for both construction and environmental conservation. More efficient materials and applications contribute to sustainable development goals, aligning with global efforts to reduce environmental impact.

Conclusion

In conclusion, geotextile fabric plays a pivotal role in enhancing infrastructure stability, especially in the context of Indonesia’s diverse construction landscape. From mitigating soil erosion to supporting sustainable development, the fabric’s versatility makes it an invaluable asset in engineering projects. As the industry continues to evolve, embracing geotextile technology is crucial for ensuring resilient and environmentally responsible construction practices.

For more information about Geotextile Non Woven Factory in Indonesia, please contact: Whatsapp/Mobile Phone : +62 811 1721 338 (Ms. Ratna), or: Email : [email protected].